Introduction to Main Types and Use of Refractories for Iron and Steel Industry

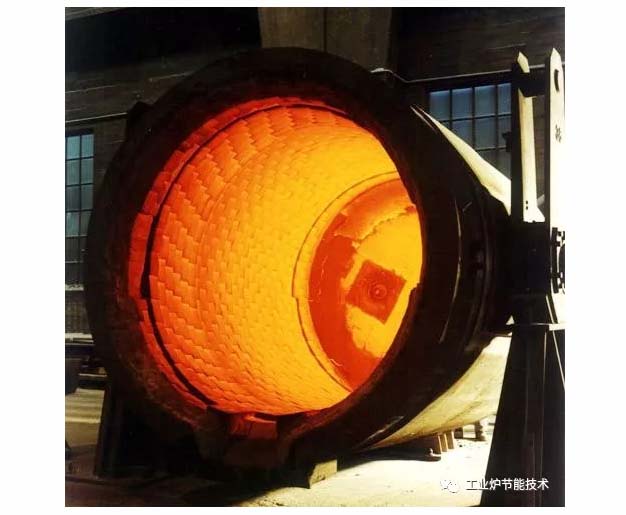

converter refractories

In converter steelmaking, a water cooling technique and a suspension system are applied in the upper cone and lower barrel of the converter shell respectively, which can reduce the deformation of the converter body, prolong the life of the converter lining and increase the productivity of the converter. The application of these new technologies has had some influence on the use of refractories. It will not be a problem to increase the service life of the converter to above 4000, in addition to spraying, the application of high-lime and dolomite and the application of slag splashing technology, and the furnace age is over 10000 times. This is a development direction worthy of the attention of the producer of refractories.

Refractory for blast furnace

The development of ceramic cups for blast furnace is more and more common, but the application of high corrosion resistance refractory is needed to ensure the service life. In addition to design changes, there have been major changes in refractory materials, such as the replacement of ordinary charcoal blocks with microporous carbon bricks to reduce the penetration of molten iron. The used clay brick is more suitable for the application requirements of taphole mud. Using grouting method to repair the lining of blast furnace can effectively prevent the erosion of the hot air flow in the lining of blast furnace, thus prolonging the life of the lining of blast furnace.

submerged nozzle for continuous casting

With the development of the continuous casting system, the tundish has changed from a transit station to a metallurgical vessel which now affects the quality of cast steel and increases the productivity of cast steel. As a result, many functional materials are gradually applied in tundish, such as slag-retaining weir, impact plate, filter, argon-blowing gas-permeable plug, etc.

As an important functional refractories for continuous casting, the submerged nozzle has been studied in two aspects: first, improving the corrosion resistance at the slag line and reducing the adhesion of Al2O3 on the inner wall. By increasing the content of ZrO_2 to 88, and by improving the size distribution of Jiahua particles, the thermal expansion rate and porosity of products can be decreased, and the slag corrosion resistance can be improved by increasing the density of ZrO_2.

In addition, close attention should be paid to technological advances in user industries, such as direct reduction iron, which has emerged in recent years, and new requirements for refractories arising from new processes such as DC electric arc furnace steelmaking.

TEL

TEL SERVICES

SERVICES MAP

MAP TOP

TOP